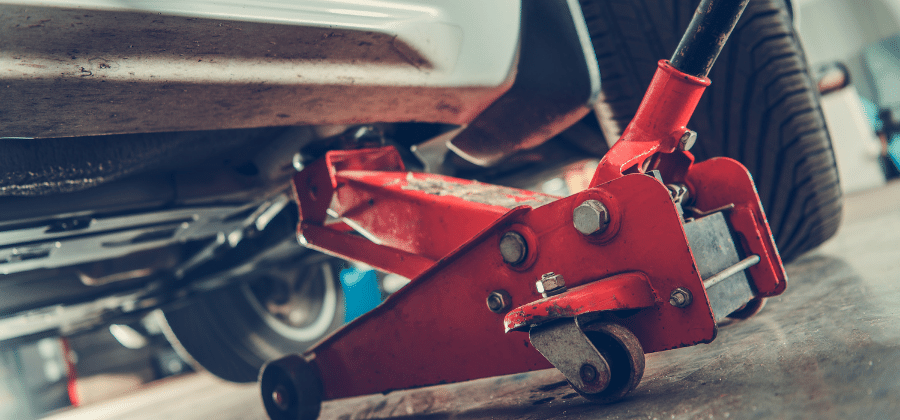

Aluminum and steel are the main elements for floor jacks or combinations of both. Thus, it is crucial to understand the meaning of aluminum versus steel jacks and ultimately determine it. As for the floor jack’s material, this particularly points out to the body (frame) and the jack’s handle.

It doesn’t matter whether they made the jack with aluminum or steel; all the floor jacks contain steel components. These parts comprise hydraulic ram subassemblies, bolts, screws, bearings, and other fasteners made of steel. Therefore, the frame and handle deal with most of the material in the floor jack.

Thus, there are few discerning factors and distinctions where one material works much better than the others. As an outcome, we have chosen all these factors to present to you in this article. So making the right choice between aluminum vs. steel floor jacks is still essential.

Related Article: Top 10 Best Aluminum Floor Jacks In 2023

Aluminum Vs. Steel Floor Jacks: Overview

As long as the jack you buy is strong enough to support the weight of the vehicle you will lift, it does not matter which kind you are using. The most important thing is that they give you everything you demand from them. So have a look at the overviews of Aluminum Vs. Steel Floor Jacks.

Aluminum Floor Jacks

Whenever you are predominantly doing DIY projects, prefer aluminum jacks. Because of their lightweight construction, they are easy to move and carry. So it will also make the installation a breeze.

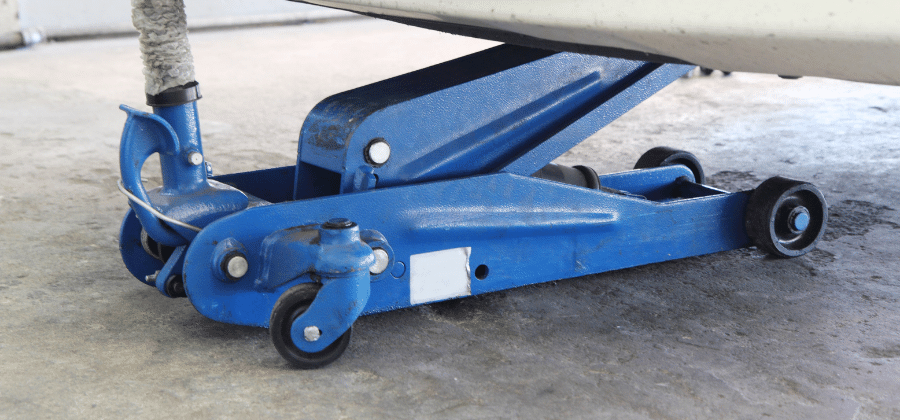

Aluminum jacks are almost flat and have four wheels; they are like skateboards with handles. Because of the wheels, you can transport it from one place to another quickly and easily in any direction.

Most aluminum jacks are 3-ton, but few are 2-ton. Maximum lifting capacity is around 4000 to 6000 pounds, respectively.

A 3-tons aluminum floor jack typically weighs approximately 60 pounds doe a single time each. However, with two aluminum jacks, the weight can be 10 pounds. These jacks are easy to lift and handle.

Aluminum floor Jacks are 50% lighter than their steel counterparts. With 6000 pounds of maximum weight capacity, you can place the aluminum jacks under various cars, lawn tractors, small campers, etc. However, because of their heavy-duty construction, they can withstand heavy loads.

Aluminum floor jacks are highly durable and can handle a good amount of wear and tear. Despite their durability, they are still instrumental and provide long-term value.

Aluminum jacks are appropriate to use in various workshops and home garages because of their corrosion resistance. The main disadvantage of using aluminum floor jacks is that they are more expensive than steel ones.

Steel Floor Jacks

So long as you make sure you get a floor jack strong enough to support your vehicle’s weight. So it would be the steel one you choose.

Although the floor jacks they construct from steel have a high density, giving them an excessive amount of strength and durability. In comparison with aluminum jacks, steel jacks are weightier. Steel floor jacks can weigh as much as 100 pounds, so you can’t simply carry them around.

In line with their aluminum counterparts, the steel floor jacks also feature wheels to make them easier to maneuver. Despite their weight, they still roll well, but not as smoothly as the aluminum.

These floor jacks can withstand the daily abuse of a busy shop that works with more substantial equipment. The material does not determine the strength of the jack, but by the way, they built it.

In damp conditions, steel can rust, but its edges are nearly impossible to blunt. Dropping heavy objects or hitting with a hammer won’t cause much damage, and they would not even dent.

Comparison of Aluminum Vs. Steel Floor Jacks

The main difference between aluminum and steel floor jack is the material they are made of. Both are excellent performers. There is no confusion about comparing aluminum vs. steel floor jack. Below, we summarize it.

| Specifications | Aluminum Floor Jack | Steel Floor Jacks |

| Material | Aluminum | Stainless steel |

| Weight | Lightweight | Heavy weight |

| Rust | Anti-rusting property | Prone to rust |

| Flexibility | More Flexible | Less Flexible |

| Purpose of use | Best for the DIY Projects | Suitable for heavy task |

| Durability | Provides reasonable time-frames | Highly durable |

| Building quality | The product can sustain a fair amount of adversity | Able to withstand outrageous abuse |

| Price | A little bit costly | Budget friendly |

Final Words: Aluminum Vs. Steel Floor Jacks

Well! The above analysis has clarified the debate between aluminum vs. steel floor jacks. The best material for a floor jack will vary; it entirely depends on your preferences.

If you prefer a lightweight floor jack and would like to spend money on more flexibility, an aluminum floor jack is the best choice.

Alternatively, if your budget is tight and you’re comfortable with a relatively heavy floor jack with high durability, you might prefer a steel jack.

In terms of strength, floor jacks’ strength entirely depends on their construction. Whether they made it of aluminum or steel makes no difference. Both materials are strong enough to propel your vehicle into the air.

So, from comparing aluminum vs. steel floor jack, you can see that both have a unique need. It is imperative to pinpoint the main reason behind using the jack and choose the most appropriate one accordingly. So we intended this guide to help you decide on the most suitable floor jacks.

I am Lucas. I am an auto enthusiast and I have many years of experience in this industry.

I created eewis.com to share my experiences and assist you to seek out the right products.